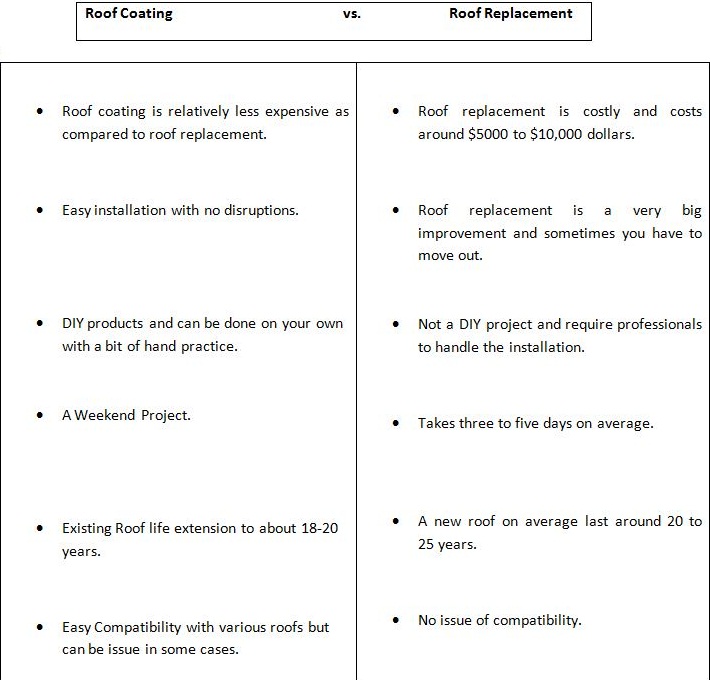

When it comes to your house,sometimes it’s the hidden, quiet monster that you should be the most afraid of e.g. Leak and trapped moisture. Especially during wet and cold winter months, it’s time to keep your eye out for your home’s worst enemy – trapped moisture.Earthquake and wind stormsare cannot be avoided but you shouldbe prepare your roof’s defense against them

We’re not talking about a house leak which of course is also a concern we are also talking about the sneaky type of moisture that comes from wet jackets and shoes, watering house plants, cooking, showering, and wet pets. All these sources of moisture evaporate into thin air, travel through the house until they find a cool wall surface, toilet tank, or even a thermal pane window to turn back into a liquid state.

When this moisture finds these cool lower corners of the house, it sticks and stays, creating a little environment for mold and mildew. None of this is good and it can be easily prevented. The outcome of this moisture is normal wear & tearthings like peeling paint, curling shingles, rotted skirting, mold, and mildew and bug damage. These are not good for you home décor and can be prevented with proper ventilation and timely maintenance.

However, the good news is that specific vents can be installed in your roof, foundation, bath and kitchen to take care of the excess moisture; also you can coat your Roof with EPDM coatings Liquid Rubber to avoid water leaks and ponding.

Quoted: Experts recommend that homes in our area should have one square foot of ventilation for every 150 square foot of foundation floor area. Same for the attic using roof vents. For example, a one-floor 1,200-square-foot house, divided by 150, would need 8 square feet of ventilation around the perimeter of the foundation and again in the roof.This can be achieved by adding 1- square-foot foundation vents at every corner and evenly spaced around the foundation or skirting. By installing these vents you have taken some of the preliminary measures needed for a healthy, home and you.

Roof Protection

A leaky roof can be the start of a long road to repairs, and if you’re a business owner, you know that those repairs can put you out of business until they’re finished and cost you a lot of fortune.You can stop leaks in their track, long before you even have to make repairs. The best way to do this is by laying down a layer of protective liquid rubber roof coating.

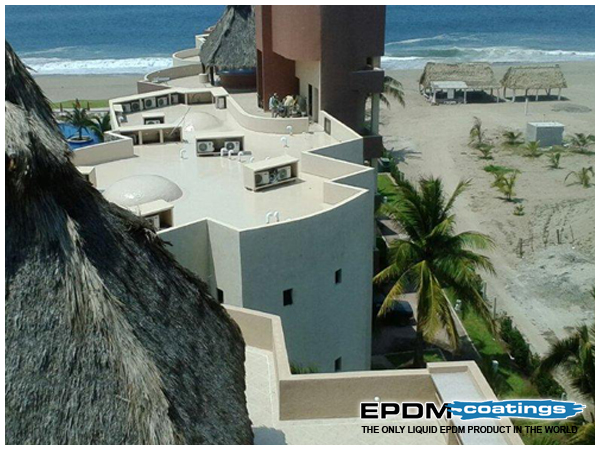

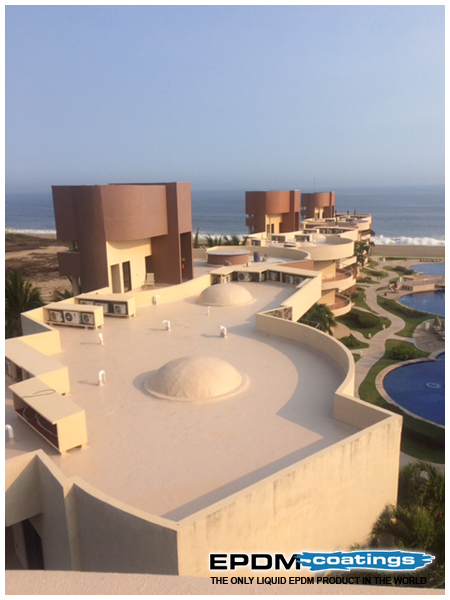

A coating like EPDM Liquid Rubber will help keep your roof in the best shape possible and it will extend the life of it for what could be decades.EPDM Liquid Rubberis an easy-to-apply solution to most of the problems that are faced by building owners. EPDM Liquid Rubber coatings come in liquid form that has to be painted on or sprayed and allowed to dry so it cures and creates an airtight, watertight, and UV resistant seal over the entire surface of the top of the building.

“Using a product like EPDM Liquid Rubber gives you total coverage and protection in just a single coat.”

EPDM Liquid Rubber: Is It Worth It?

Whether coating your Roof with EPDM coatings Liquid Rubber is worth it or not? The answer is resounding yes it is. The number one reason that causes damage to a home or commercial building is water that comes in through the roof.

The roof of a building is continuously exposed to rain, snow, ice, wind, dirt, debris, UV rays, hail, and so much more. All of those elements can cause extensive damage to the roof and vulnerable the interior of the structure to even more damage. When the roof of the building gets compromised, it allows the outside elements to come inside and creates more problems in the interior.You could potentially prevent thousands of dollars in repairs and full Roof replacements by applying one of the EPDM Liquid Rubber roof coatings to a building’s rooftop.

How Much Do Rubber Roof Coatings Cost?

Obliviously, coating your roof involves costs but applying EPDM Liquid Rubber to the roof will eventually save you money in the long run. First EPDM Liquid Rubber is one coat application which means no need to re-coat the Roof again and again. Secondly, a Roof coated with EPDM Liquid Rubber should last 18-20 years more than its average life. Finally, EPDM Liquid Rubber does not need a primer as well. How much it will cost you up front? Some of the price will be determined by how big the surface of your roof is. You’ll need to measure the length and width of the roof to get the coverage area. You’ll then purchase the amount of product needed to cover that surface.

Contact us today at 855-281-0940 as our experts are always willing to help. Make sure to visit us on https://www.epdmcoatings.com/liquid-rubber.php for more news, tips, and information on the best ways to care for your Roof.